Deep reactive ion etching (DRIE) is a type of reactive ion etching aimed at creating very deep,

high aspect ratio structures. While a standard RIE process can be used, they are often inadequate

so a couple of variations have been developed for specific applications. The most common

variant is the Bosch process, used mainly for etching silicon substrates. It is also possible to use

cryogenic etching to create a high aspect ratio etch in silicon, compound semiconductors, and

some polymers. It was developed for microelectromechanical systems (MEMS), which require

these features, but is also used to excavate trenches for high-density capacitors for DRAM.

The Bosch process, named after the German company Robert Bosch GmbH which patented the

process, also known as pulsed or time-multiplexed etching, alternates repeatedly between two

modes to achieve nearly vertical structures:

- A standard, nearly isotropic plasma etch. The plasma contains some ions, which attack the

wafer from a nearly vertical direction. Sulfur hexafluoride [SF6] is often used for silicon. - Deposition of a chemically inert passivation layer. (For instance, Octafluorocyclobutane [C4F8]

source gas yields a substance similar to Teflon.)

Each phase lasts for several seconds. The passivation layer protects the entire substrate from

further chemical attack and prevents further etching. However, during the etching phase, the

directional ions that bombard the substrate attack the passivation layer at the bottom of the trench

(but not along the sides). They collide with it and sputter it off, exposing the substrate to the

chemical etchant. These etch/deposit steps are repeated many times over resulting in a large number

of very small isotropic etch steps taking place only at the bottom of the etched pits. To etch through

a 0.5 mm silicon wafer, for example, 100–1000 etch/deposit steps are needed. The two-phase

process causes the sidewalls to undulate with an amplitude of about 100–500 nm. The cycle time

can be adjusted: short cycles yield smoother walls, and long cycles yield a higher etch rate.

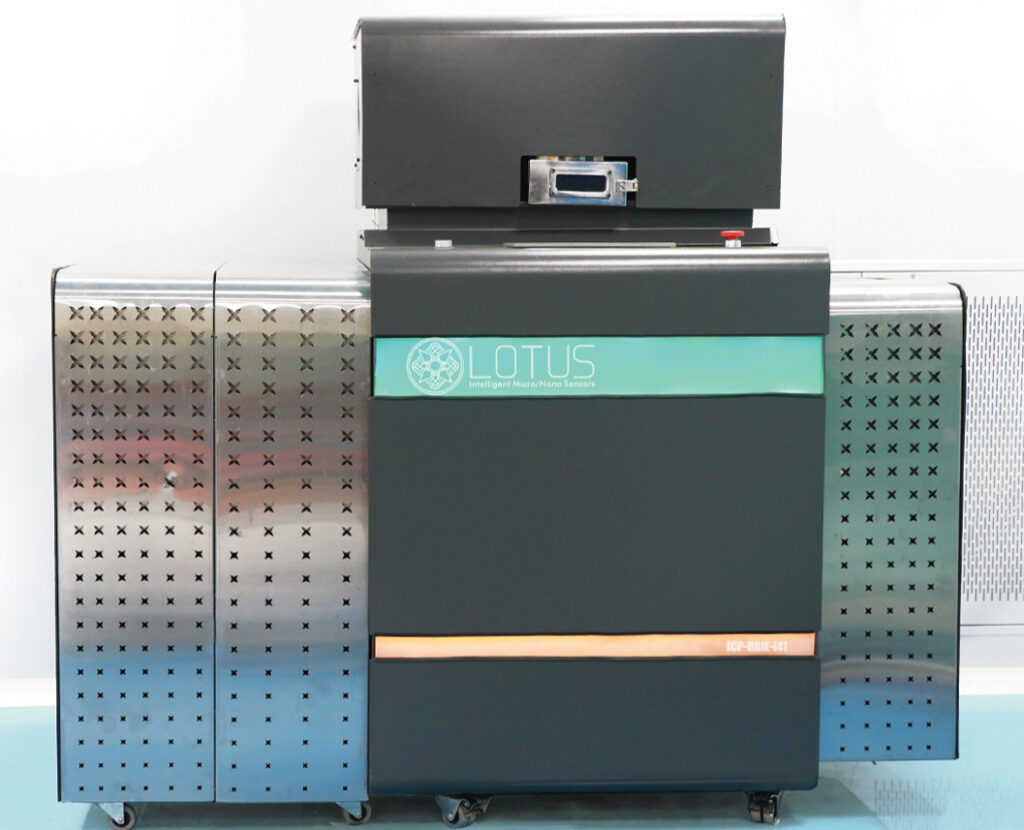

Feature and benefit

Lotus Deep Reactive Ion Etch (DRIE) is tool used to etch 4″ (100 mm)

silicon wafers using the Bosch process. It has a high power ICP source

and is capable of fast, high aspect ratio anisotropic etching of silicon.

Fast-acting, high precision MFCs and pendulum valve and a turbo pump

provide fast switching times, enabling reduced undercut and sidewall

roughness. Etch rate varies with feature size and density, so a

characterization run is strongly recommended with any new mask.

- High etch rates are achieved by high ion density and high radical density

- Control over selectivity and damage is achieved by low ion energy

- Separate RF and ICP generators provide separate control over ion energy and ion density, enabling high process flexibility

- Low pressure processing yet still high density for improved profile control

- Chemical and ion-induced etching

- High conductance pumping port provides high gas throughput for fastest etch rates Wafer clamping and cooling as standard, providing excellent temperature control