Evaporation is a common method of thin-film deposition. The source material is evaporated in a vacuum. The vacuum allows vapor particles to travel directly tothe target object (substrate), where they condense back to a solid state. Evaporation is used in microfabrication, and to make macro-scale products such as metallized plastic film. Any evaporation

system includes a vacuum pump. It also includes an energy source that evaporates the material to be deposited. In the thermal method, metal material (in the form of wire, pellets, shot) is fed onto heated semimetal (ceramic) evaporators known as “boats” due to their shape. A pool of melted metal forms in the boat cavity and evaporates into a cloud above

the source. Alternatively,the source material is placed in a crucible, which is radiatively heated by an electric filament, or the source material may be hung from the filament itself (filament evaporation). Evaporation is commonly used in microfabrication to deposit metal films. Common metals include carbon, gold, gold/palladium, and platinum.

Feature and benefit

- Turbo molecular pump to provide fast and clean oil free high vacuum

- User friendly front panel color LCD based touch screen Siemens HMI control

- Siemens PLC based process automation with recipe

- Substrate heating facility up to 300°CThree different material can be deposited individually and at the same time

- Three different material can be deposited individually and at the same time

- Isothermal sample holder

- Full range pressure measurement

- Fully rotational stage design results in outstanding process control which guarantees superior uniformities and low operational costs.

- Recipe guarantee: offers starter recipes for every process utilizing its extensive library of process recipes with guaranteed process verification.

- High resolution film thickness monitor

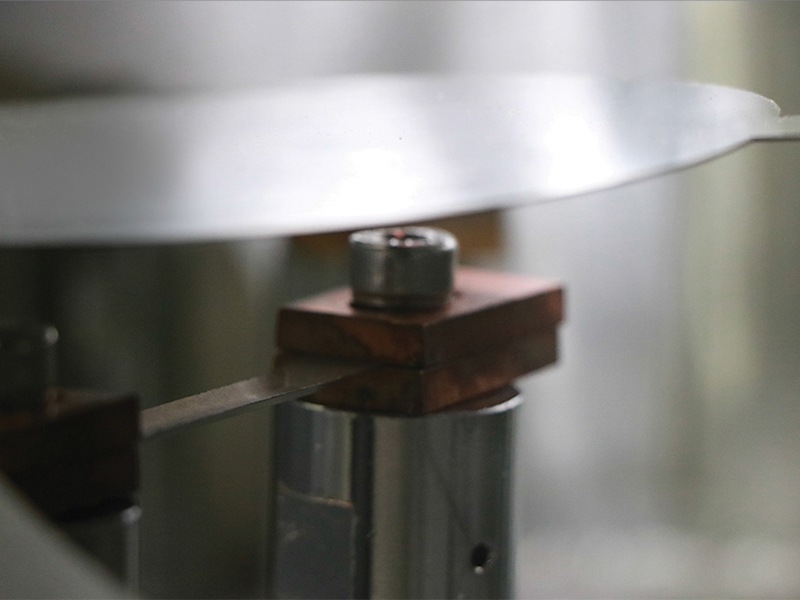

- Shutter Assembly for All Sources

- Maintenance friendly mechanical design.