Our furnace is designed to perform oxidation & diffusion process on a 4inch silicon wafer.

Oxidation Furnaces

Oxidation is the groundwork for all of the semiconductor fabrication processes.

The oxidation process creates an SiO2 layer, which serves as an insulating layer that blocks

leakage current between circuits. The oxide layer also protects the silicon wafer during

the subsequent ion implantation and etching processes. In other words, the silicon dioxide

layer serves as a reliable shield during the semiconductor manufacturing process.

Thermal oxidation can be either wet or dry, depending on the gas used for the oxidation

reaction. Dry oxidation uses pure oxygen (O₂), and consequently, the oxide layer grows

more slowly, making it ideal for creating a thin layer. Oxides created by the dry method

have excellent electronic properties. Wet oxidation uses both oxygen (O₂) and vapor (H₂O)

As a result, the oxide layer grows faster and forms a thicker layer. However, oxides created by

the wet method are not as dense as those created by dry oxidation. Under identical time

and temperature conditions, the oxides formed by the wet method are about five to ten times

thicker than those formed by the dry method.

Diffusion Furnaces

In semiconductor production, doping is the intentional introduction of impurities into

an intrinsic (undoped) semiconductor for the purpose of modulating its electrical,

optical and structural properties. The doped material is referred to as an extrinsic semiconductor.

Feature and benefit

- 1100°C Precision – Highest operating temp in class for advanced SiO2 growth & doping.

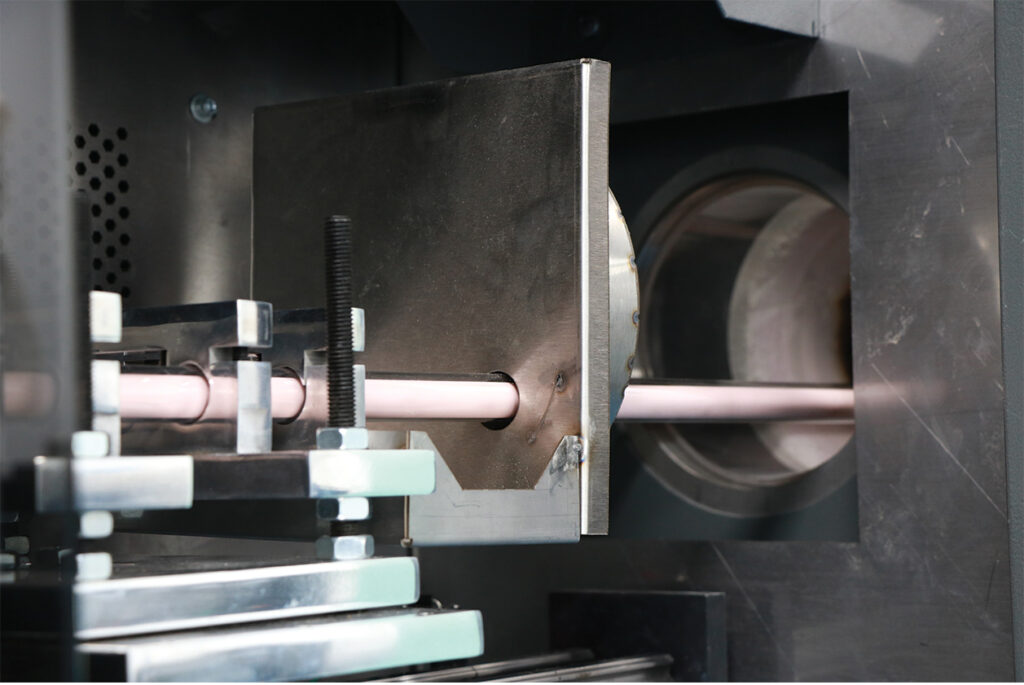

- 6-inch Tube Compatibility – Processes 4″ wafers with room for R&D customization.

- 3-Zone Smart PID – ±1°C uniformity via independent/master-slave control.

- Siemens PLC Automation – Full recipe control for unattended 24/7 operation.

- Optional Water Cooling – Enables rapid cooldowns (30% faster cycle times).

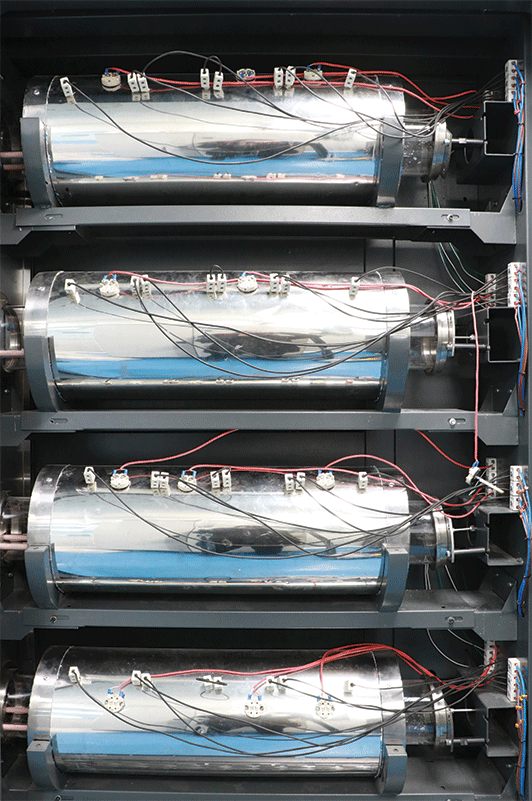

- 4-Tube Stack Design – Run oxidation, doping, and annealing simultaneously.

- Zero Cross-Talk – Isothermal chambers prevent thermal interference.

- Contactless Loading – Automated boat-in-tube reduces contamination risk.